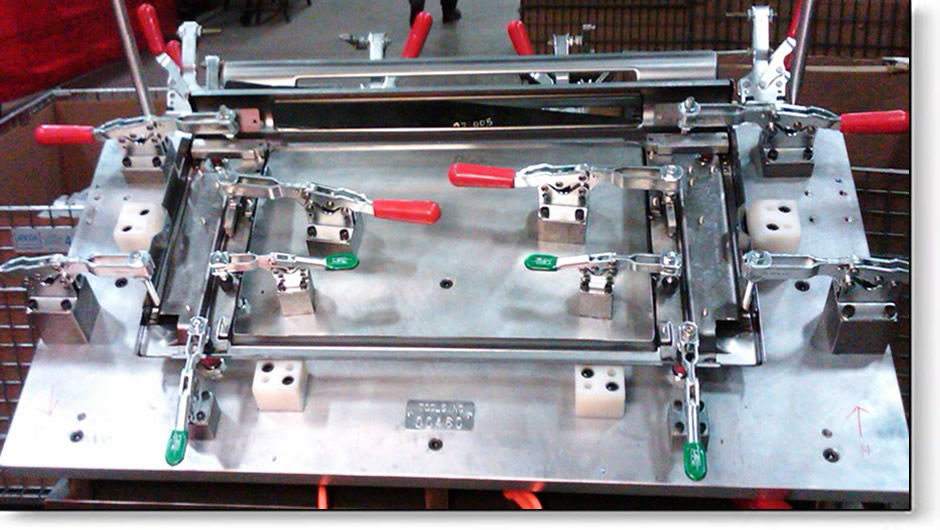

* STAMPING

* DEEP DRAW * PROGRESSIVE * MODEL TRIM

* LASER CUTTING

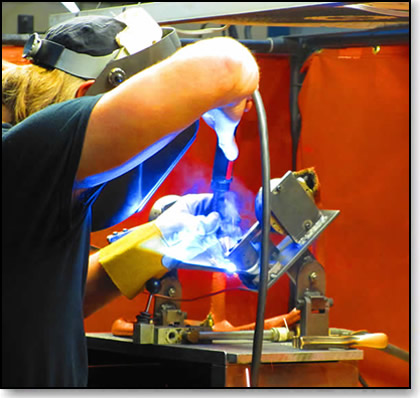

* WELDING PROCESSES

* ADHESIVE BONDING

* MECHANICAL ASSEMBLY

* FINISHING

* PACKAGING

Over 50 years of experience, Tools Inc. has established a business craft our customers that rely on Quality

Our Product history is diverse to meet any need.

Over 50 years of experience, Tools Inc. has established a business craft our customers that rely on Quality

Our Product history is diverse to meet any need.

Over 50 years of experience, Tools Inc. has established a business craft our customers that rely on Quality

Our Product history is diverse to meet any need.